Midwest Hardwood Company selling lumber

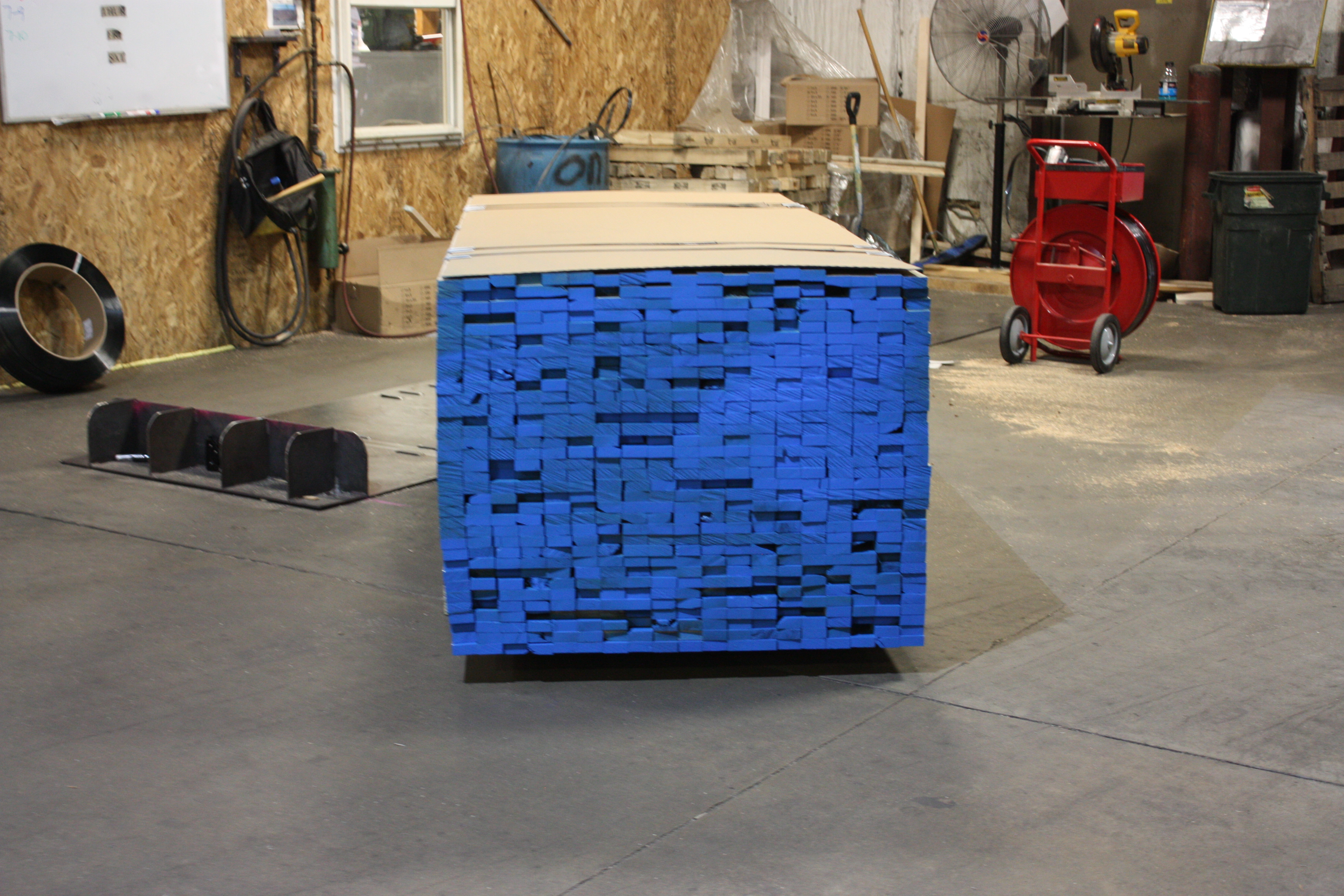

Ripped-To-Width Lumber

Few things are more important to the profitability of a hardwood products manufacturer than lumber yield. Although our industry was established on the standard of normal, random width lumber, many companies today, especially flooring manufacturers cannot allow the waste that often develops with random width lumber. For those companies Midwest Hardwood offers lumber ripped to precise width after kiln drying. The bottom line is better, more consistent yields and higher profits.

Our industrial gang rip saws are computer optimized to capture the most usable fiber from every board. Automated materials handling and movable arbors allow high volume efficiency and flexibility. Our broad customer base often allows us to combine the cutting bills of several customers in order to maximize yield and help each customer hold down production costs. In some cases we can even begin a customized strategy all the way back at our sawmills.

Benefits to Ripped to Width lumber:

- Higher yield expectations

- Lower per unit freight costs

- Lower variability in conversion costs

- Less purchasing time

- Conversion and re-purposing of valuable plant space

- Potentially lower labor costs

See our ripped-to-width PDF product sheets below.

Footer